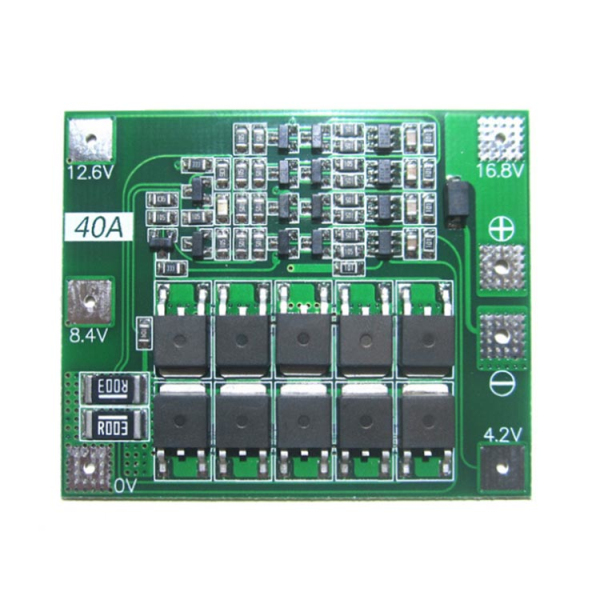

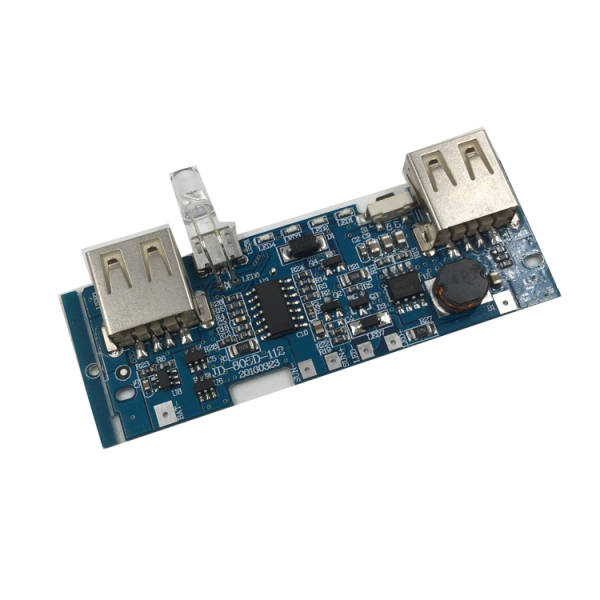

Electronic Resistor And Capacitor

Basic Info

Model No.: SMT PCB Electronic Resistor And Capacitor

Product Description

What is the difference between SMT and SMD?

SMD; it is the abbreviation of Surface Mounted Devices, meaning: surface mount device, it is a kind of SMT (Surface Mount Technology) Electronic Components. In the initial stage of electronic circuit board production, the via assembly is completely completed manually.

SMT: It is a kind of leadless or short lead surface mount components (SMC/SMD for short, chip components in Chinese) mounted on the surface of the Printed Circuit Board (PCB) or the surface of other substrates , Circuit assembly technology that is assembled by soldering and assembly by reflow soldering or dip soldering.

2. smd is a component that adapts to this mounting technology, and it is a specific object. The role of SMD is different. After the first batch of automated machines are launched, they can place some simple pin components, while SMT is a circuit device that mounts no-lead or short-lead surface mount components on the surface of a printed circuit board. Even technology.

4. SMT is a kind of surface mount components without leads or short leads (SMC/SMD for short, chip components in Chinese) mounted on the surface of Printed Circuit Board (PCB) or other substrates , The circuit assembly technology of soldering PCB assembly through reflow soldering, Wave Solder for PCBA or dip soldering.

SMT

Material loss

1. The suction nozzle is deformed, blocked, damaged, insufficient vacuum pressure, and air leakage, causing the material to be sucked, incorrectly reclaimed, and the recognition is not passed, and the material is thrown away. Solution: require technicians to check the equipment every day, test the NOZZLE center, clean the suction nozzle, and maintain the equipment regularly as planned.

2. Insufficient spring tension, uncoordinated suction nozzle and HOLD, unsuccessful ups and downs cause poor picking; Solution: Regularly maintain the equipment as planned, check and replace vulnerable parts.

3. Deformation of HOLD/SHAFT or PISTON, bending of the suction nozzle, and shortening of the suction nozzle, resulting in poor reclaiming; Solution: Regularly maintain the equipment as planned, check and replace vulnerable parts.

4. The reclaiming material is not in the center of the material, and the reclaiming height is not correct (generally press 0.05MM after touching the part), resulting in deviation, incorrect reclaiming, offset, and identification does not match the corresponding data parameters The recognized system is discarded as invalid materials; solution: regularly maintain the equipment as planned, check and replace vulnerable parts, and correct the origin of the machine.

5. The vacuum valve, vacuum filter element is dirty, there is foreign matter blocking the vacuum pipe channel, and the vacuum is not enough at the time of suction. The operating speed of the equipment causes poor feeding; solution: the technician must clean the suction nozzle every day and regularly maintain the equipment according to the plan.

6. The positioning of the machine is not level, the vibration is large, the machine and the FEEDER resonance cause poor material retrieval; solution: regular maintenance of the equipment according to the plan, check the level of the equipment to fix the support nut.

7. The screw rod and the bearing are worn and loose, causing vibration and stroke change during operation, resulting in poor feeding; Solution: It is strictly forbidden to blow the inside of the machine with an air gun to prevent dust, debris, and components from sticking to the screw rod. Regularly maintain equipment as planned, check and replace vulnerable parts.

8. Motor bearing wear, barcode reader and amplifier aging cause machine origin to change, operating data is inaccurate and poor material retrieval; solution: regularly maintain equipment as planned, check and replace vulnerable parts, and correct machine origin.

9. The vision, laser lens, and suction nozzle reflective paper are not clean, and there are debris that interferes with the camera's identification, causing poor handling; solution: require technicians to check the equipment every day, test the NOZZLE center, clean the suction nozzle, and maintain the equipment regularly as planned.

10. Identify the improper selection of light source, the aging of the lamp, the insufficient luminous intensity, and the insufficient grayscale to cause poor processing; solution: regularly maintain the equipment as planned, test the brightness of the camera and the brightness of the lamp, check and replace vulnerable parts.

Product Categories : Components Sourcing > Electronic Resistor And Capacitor